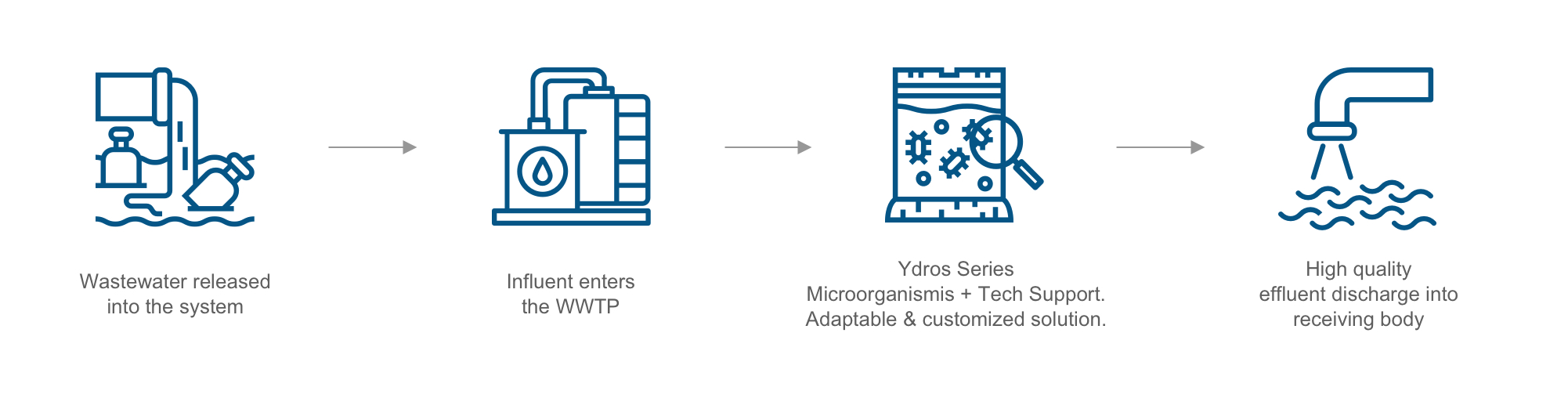

HOW THE YDRO PROCESS WORKS

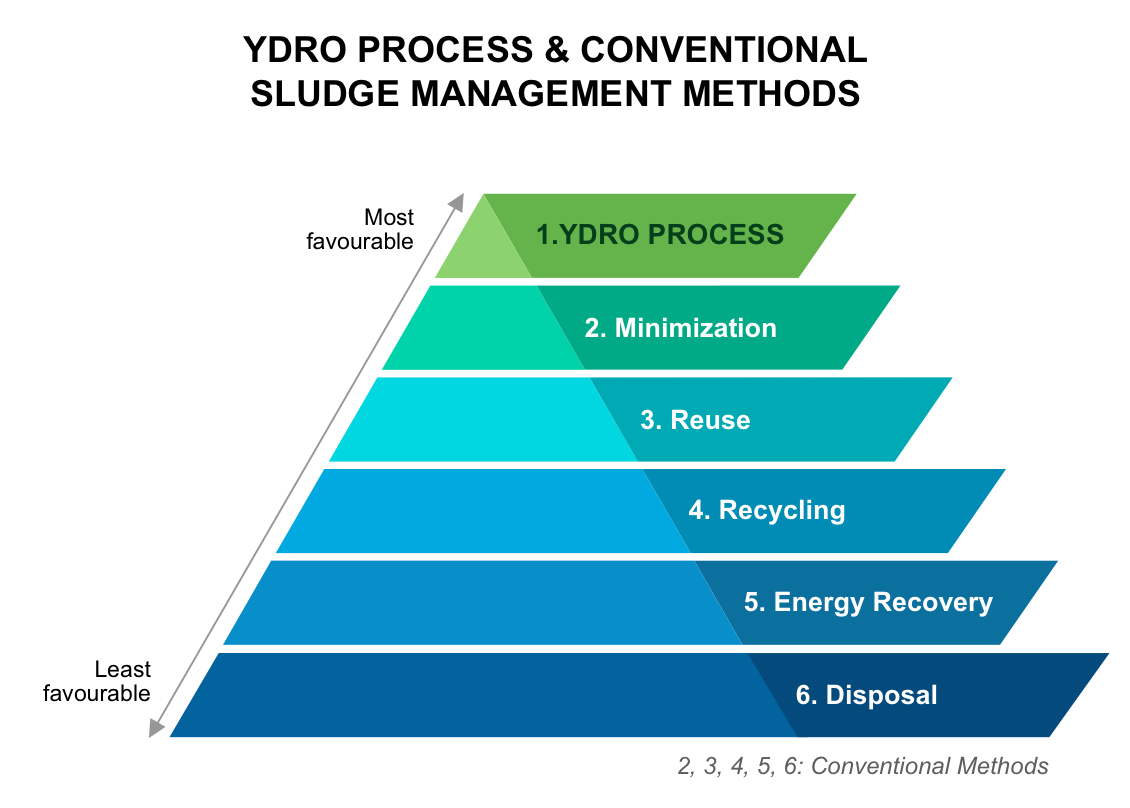

- The Ydro Process® Microbial populations continually adapt to changeable conditions to ensure targets are consistently met

- Added bacteria become dominant and existing bacteria adapt and is assimilated

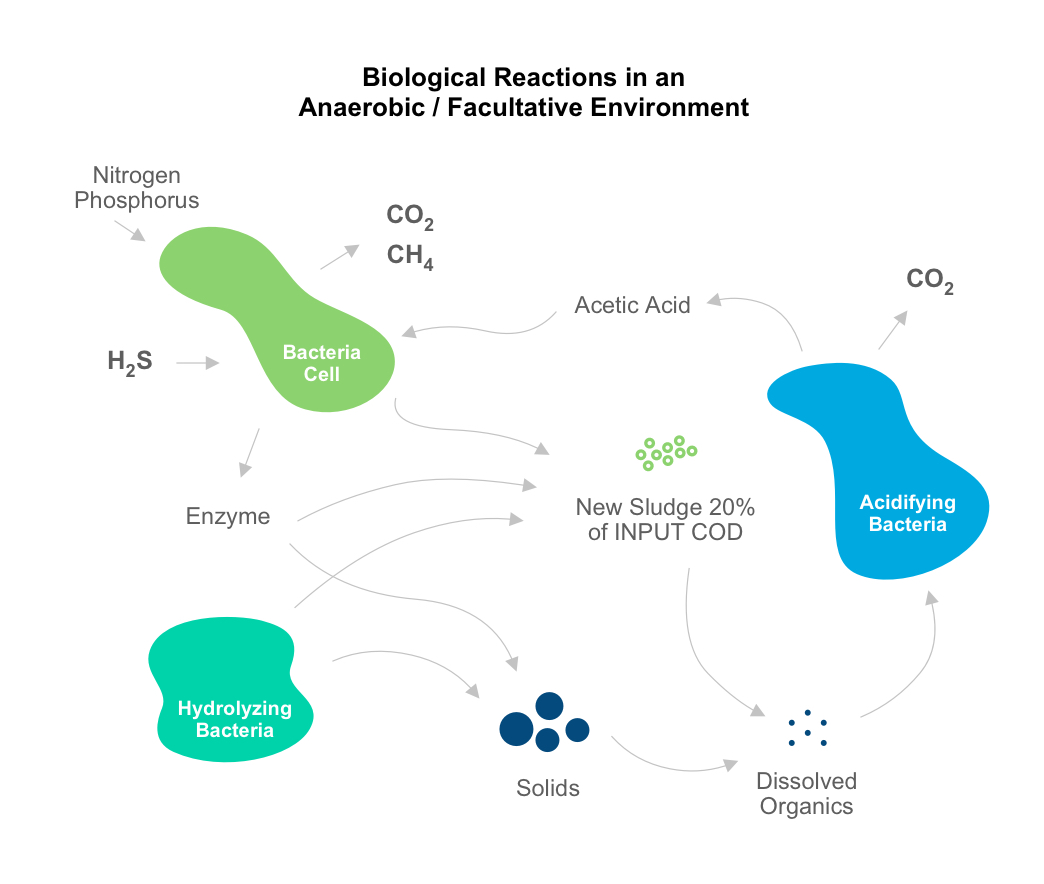

- Added microorganisms produce enzymes which enhance the biological process

- Degradation of complex organic molecules, oils and greases into simple ones leads to production of Volatile Fatty Acids (VFAs), i.e. Acetic, Butyric, Propionic Acid etc

- VFAs are then easily converted to Carbon Dioxide (CO2) and water (H2O) in aerobic conditions and methane (CH4) and hydrogen (H2) in anaerobic conditions – and also into free, available energy

- Molecular breakdown and destruction in 80% of total biomass via a metabolic pathway, Catabolism. Only 20% of total biomass is utilised for new bacteria synthesis

All of Our Microbial Products

- Are naturally occurring bacteria

- Are NOT animal derived

- Are NOT genetically modified (NON-GMO)

- Are NON-toxic and NON-pathogenic

- Include additional strains according to the treated waste

- Require a maturation time

- Contain 109 c.f.u in each gram

- Duplicate their population every 20 minutes during the maturation time

- Works in 4ºC and above

The Ydro Process® creates suitable and optimum conditions for the growth, the reproduction and the operation of the microbial product which contains:

- Hydrolyzing Enzymes

- Facultative cultures

- Aerobic cultures

- Micronutrients

- Bio-enhancers

Biological reactions

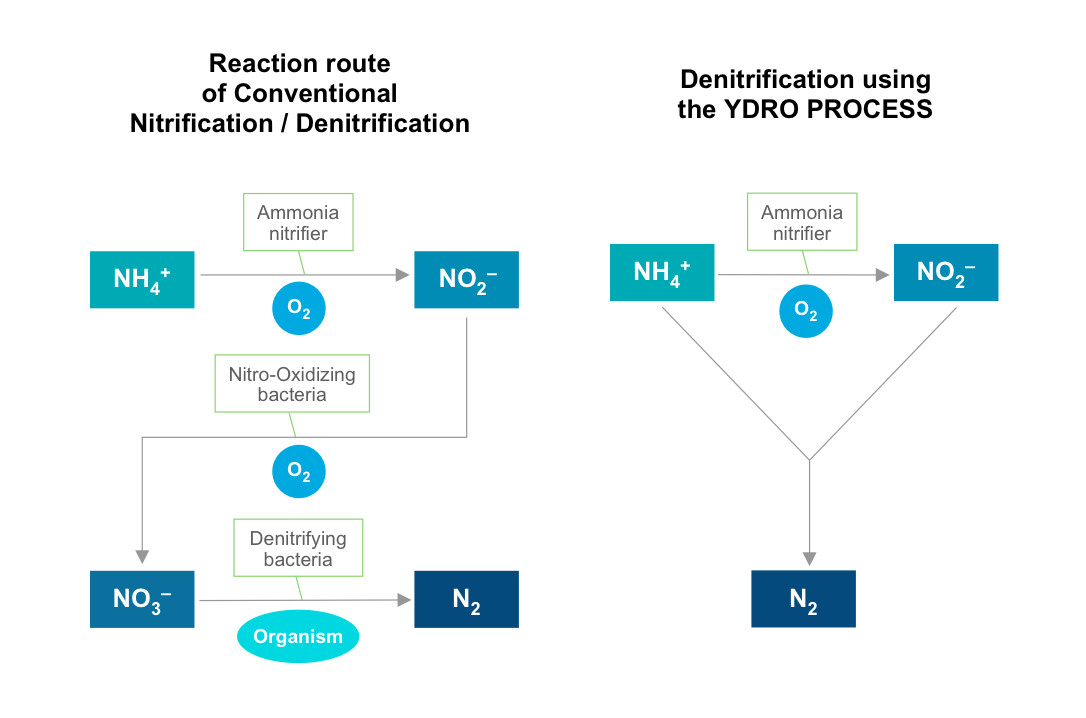

The Nitrogen Cycle with the Ydro Process®

The degradation process of Nitrogen

Part of our bacteria promote this Nitrogen cycle – Anammox (Anaerobic Ammonium Oxidation). The main advantage is that only half of the Ammonium has to be converted to Nitrite. Hence, it leads to substantial energy savings as less oxygen is required. Ammonia (NH4+) is converted to Nitrites (NO2–) then Nitrogen (N2), without first being converted to Nitrates (NO3–) – where highest Oxygen usage occurs.

Implementing the Ydro Process® in the sewer grid:

- Eliminates the city odours(grids, manholes, pumping stations)

- Degrades Fats/Oils/Grease

- Cleans out the grid, manholes and pumping stations – no cleaning/ unclogging required

- A sewer system becomes a pre-treatment reactor where anaerobic/facultative/aerobic conditions allow degradation of organic load of up to 80% (<100 mg/lt COD). WWTP then requires less time/ energy to treat remaining load.

- Ydro products contain Sulphate Reducing Bacteria which blocks formation of Hydrogen Sulphide (H2S) (cause of odours/formation of Sulphuric Acid (H2SO4)) and so prevents sewer pipeline corrosion – this results in huge savings in repair costs.

APPLICATIONS OF THE YDRO PROCESS

The Ydro Process® has been successfully applied in:

- Municipal wastewater treatment plants

- Sewer grid systems, large hotel groups and septic tanks

- Composting and fertilizer production sites

- Breweries

- Milk and dairy industries

- Organic residue treatment plants and anaerobic digesters

- Slaughterhouses and poultry industries

- Fish and aquaculture industries

- Textiles and tanneries

- Textiles and tanneries

- Fruit, juice and soft drinks industries

- Olive processing industries

- Steel and aluminum industries

- Oil and gas industries and refineries

- Landfills

- Papermills and wood processing industries

- Lakes, ponds and lagoons

- Agricultural applications: Greenhouse and flower farming

- Closed loop cooling water systems